In today’s world, where eating healthy is big, millets grab attention – packed with fibre, protein, along essential minerals. Rather than going for oats or wheat, folks pick foxtail, pearl, or sometimes rage for warm breakfast bowls or bread without grains. But as demand climbs, there’s more risk of ending up with poor-quality batches. When purchasing – as a store operator, producer, or just filling your kitchen shelves – testing what you get helps skip dangers, bad nutrients, plus money down the drain. This guide looks at smart ways to check millet suppliers from sellers, focusing on four key parts: moisture levels, cleanliness, additives, or lack of them, along with grain size. Hit each point hard – so you’re sure your batch is safe, genuine, and possibly of solid quality.

Why Quality Testing Matters for Millets

Millets survive rough conditions, which means they’re tough and good for you. Yet poor harvesting, storage, or handling can lead to spoilage or contamination. Bad lots might have toxic moulds, chemicals, or foreign matter – making them unsafe. With markets packed full of local and imported products, verifying quality protects your cash and reputation. Insisting on tight inspections isn’t just caution – it supports fair trade networks while rewarding farmers who provide clean, high-quality grain.

1. Moisture Content Test: Preventing Spoilage and Mould Growth

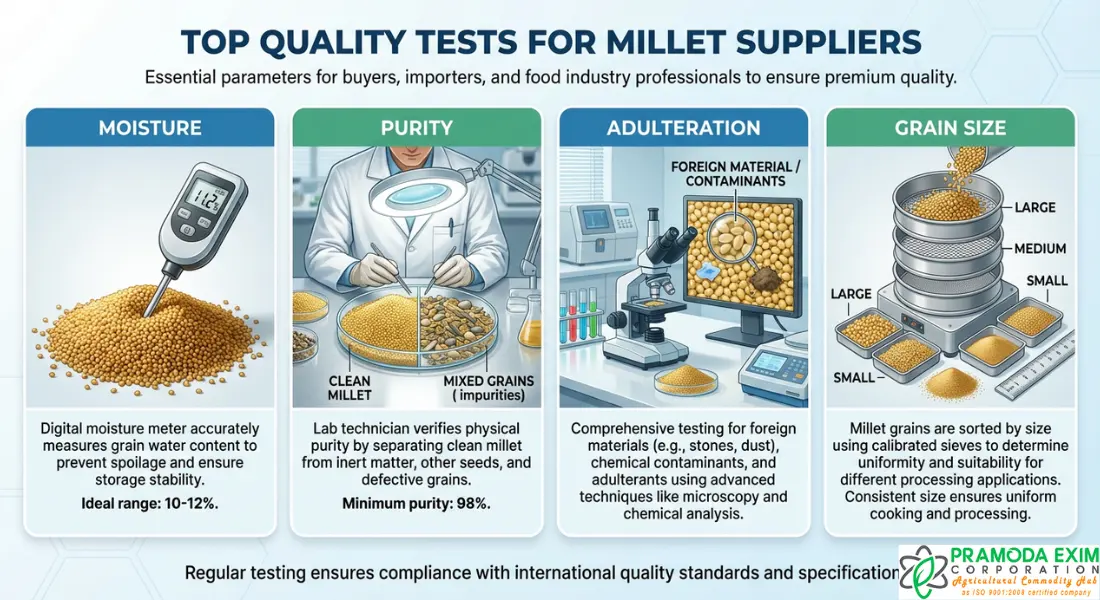

Moisture affects how long millet suppliers keep their quality. When humidity is high, mould or decay can start – this makes it spoil faster and lose nutrients. To store or use it well, keep the moisture below 12–14%.

Why Demand This Test?

Wet grain invites pests while boosting a toxin tied to cancer – known as aflatoxin. To stay safe, buyers should demand checks from sellers through reliable methods such as oven drying or moisture meters instead. Look at India’s standards – they’re specific: pearl millet must remain below 12%, and finger millet can’t go past 14%. Without confirmed test results, things get risky.

How to Interpret Results

If it’s overly damp, grains might turn mushy or clump up. A crunch stays fresher when moisture levels stay low. Pick ones tested by a third-party lab – ask for proof. This step counts extra when sending big batches across long distances.

2. Purity Test: Ensuring Authenticity and Nutritional Integrity

Purity’s about what portion of the batch is full millet grains, no broken pieces, husks, or odd stuff mixed in. If the kernels remain uncracked, they hold onto their nutrients – think solid protein levels plus key minerals.

Why Demand This Test?

Fake or impure millet suppliers could cut your results while sneaking in nasty extras. Certain vendors mix cheaper grains or fillers – just trying to keep costs down. Request proof on actual grain levels; aim for at least 95% pure stuff using high-quality varieties. Methods like sieving or inspecting closely help catch foreign particles.

Real-World Implications

Finger millet, also called rage, packs plenty of calcium – but blending it with cheap grains weakens its value. Rather than relying on vendors alone, shoppers picking up healthy staples might ask for lab checks done by certified centres like FSSAI-recognised ones. When purity’s confirmed, you gain top-tier nutrition while supporting honest farmers at the same time.

3. Adulteration Test: Detecting Harmful Contaminants

Fake bits sneak into millet suppliers because some sellers blend in dyes made in labs, leftover crop sprays, or random fillers – not real grains – just to fake a richer colour or bump up weight. These shortcuts might end in rough outcomes, say, nausea or worse from swallowing harmful junk.

Why Demand This Test?

Millets are often tested for harmful metals, pesticides, or mould by-products. Methods like HPLC or atomic absorption detect added fillers. Buyers need complete lab reports – organic versions shouldn’t contain synthetic additives.

Key Checks to Insist On

Look at leftover pesticides – store them following local rules or advice from WHO.

Test dirt for lead – or arsenic – common near busy roads – or mercury hiding below ground.

Look out for stones, sand, or tiny plastic pieces – they could mess things up or make stuff unclean.

In regions like Africa or Asia, where many eat millets every day, scams involving counterfeit goods reveal just how vital alertness is. Because buyers demand inspections, protection spreads to consumers and helps uphold marketplace standards.

4. Grain Size Test: Assessing Uniformity and Processing Quality

Grain size reveals how well millets were cleaned. If bits match, they cook evenly and look tidy – when varied, it’s likely due to careless milling or mixed lots.

Why Demand This Test?

Large kernels crush more smoothly into powder, but small chunks might signal harm or underdevelopment. To test this, workers rattle portions through fixed mesh openings – pearl millet, for example, passes easiest when bits are between 2 and 3 mm across. Shoppers ask for splits based on dimensions to keep quality consistent.

Benefits for Buyers

Grains that are the same size tend to cook better, changing how long they take and what they’re like when done. Baking can turn out uneven if the pieces vary – some spots may end up underdone or too crisp. People who sell grain should tell you about the size; most do this using lasers or sifting tools. Exporters pay close attention because customers keep asking for specific kinds, say “large” or “medium-sized.”

How to Demand These Tests from Suppliers

Fuelled by your knowledge, here’s a method for managing quality checks – use what works, or try something new; it depends on the task at hand, while keeping things clear and moving forward without overcomplicating each step along the way.

1. Agreements need straight-up rules: require lab evidence showing moisture levels, purity, no added junk, or grain size before delivery – skip acceptance if results fall short.

2. Pick reliable labs – choose ones with ISO approval or government support. In India, spots backed by BIS or FSSAI tend to give dependable outcomes.

3. Hire external testers when buying expensive stuff – skip relying only on what sellers say.

4. Fewer checks may cut costs today – yet missing steps can spark trouble down the road, such as angry customers or unsafe products. Maybe team up with suppliers so each one covers part of the test cost.

5. Look into stuff every so often – toss in surprise check-ins to hold momentum.

The Broader Impact: Health, Environment and Economy

Demanding these checks goes beyond personal gain. High-quality millet improves digestion while balancing blood sugar. Environmentally, it encourages natural farming without harsh chemicals. Financially, farmers get fair prices – boosting trust among buyers at the same time.

In spots like the U.S. or Europe, since millet arrives from overseas, strict guidelines by health agencies mean inspections still apply – meaning if importers ignore them, fines often follow, proving just how key these steps are across the globe.

Common Pitfalls and How to Avoid Them

Overlooking small vendors? Test local sources fast – start with humidity or quality instead. Skipping certs? Look at labels – stuff like Organic or Non-GMO usually means checks were done. Fair Trade can signal actual monitoring. Appearances lie – shiny grains might hide added stuff, so demand real evidence instead.

In today’s busy market, decent quality isn’t optional – it’s basic. Rather than cutting corners, check every batch for moisture, purity, false fillers, also grain size so each bag delivers safe nutrition. Whether you’re stocking a health-focused store or feeding your family, these tips let you choose better. Remember – reliable millet suppliers are more than fuel; it reflects concern for health and truth. Start demanding these tests now – even small changes boost your confidence big time. Looking for better sourcing ideas? Take a peek at our other articles.